- PRODUCTS

LED Driving Lights

Halo, spot, flood, and mixed beam patterns tested in harsh environments.

LED Headlights

DOT compliant lighting in a variety of sizes, styles, and integrated amber or white halo rings.

LED Light Bars

Curved or straight, 5" to 54" lengths in white and amber for varying conditions.

Accessory Lights

Heavy-duty, waterproof underbody, strip, compartment lights in multiple colors.

LED Work Lights

Featuring a broad range of lumen outputs for light, heavy and extreme duty applications.

Commercial Lights

Interior and exterior lighting with multiple beam patterns, brackets, in AC and DC voltages.

Beacons & Specialty Lights

Safety accessories and specialized lighting solutions for a range of applications.

Vehicle Specific

Lighting kits and mounting options for most truck makes and models.

- INDUSTRIES

- SUPPORT

- ABOUT

- Cart

- Account

IMPENETRABLE DEFENSES

Vision X lights are specifically designed for harsh environments and have been tested in the most extreme conditions and are sealed to keep the environment out no matter what conditions they are used in.

Your vehicles and equipment are operated in all types of extreme environments including extreme heat, arctic snow and periodic steam cleaning. Protecting electronics from moisture and contaminants is key to a long LED life span and ensuring continual operation in conditions when you need them the most. Engineered silicone gaskets, sealed plugs, and extensive testing ensure that Vision X lights are the most reliable and durable lights on the planet and beyond.

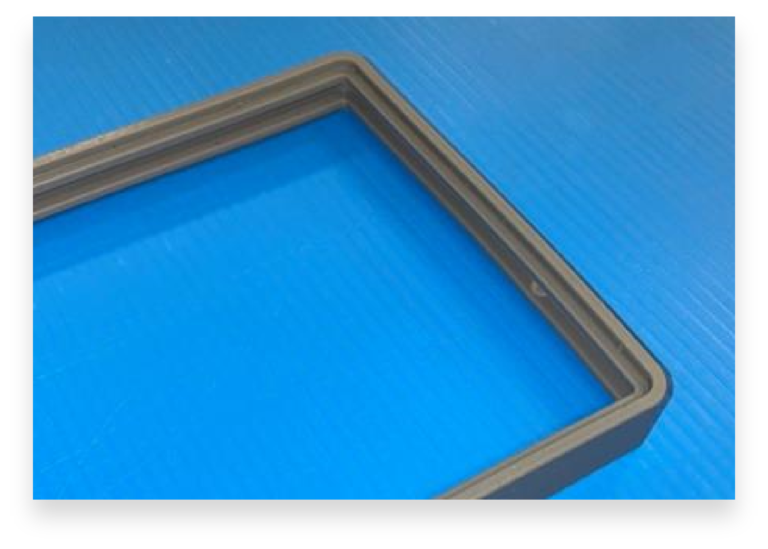

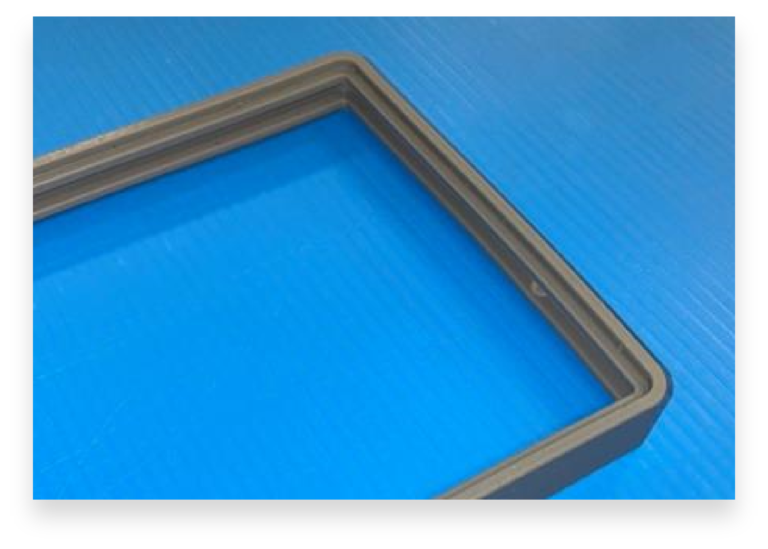

Molded Silicone Gaskets

All mating surfaces are sealed with silicone molded rubber gaskets. Silicone rubber gaskets are high-performance mechanical seals with an extraordinary resistance to extreme temperatures, weather and (UV and ozone) resistance.

Ingress Protection Ratings (IP)

The IP Code, or Ingress Protection classifies and rates the degree of protection provided by mechanical casings and electrical enclosures against intrusion, dust, accidental contact, and water.

An IP68/IP69K rating ensures that Vision X work lights are dust tight with no ingress of particles and protected against high pressure wash downs.

Cable Connections

Even the interfaces between the cabling connection and the light in mining and construction machines are subjected to extreme requirement and the housing connectors are watertight and resistant against oil, chemicals and UV radiation.

Thermal Shock

Thermal shock testing uses a chamber that contains two pre-heated and pre-cooled workspaces with a mechanism that transfers the product between the hot and cold zones during testing.

Over-Molded Connectors

Sealed connectors are a key components in keeping moisture and contaminants out. High end Deutsch over molded connections are sealed at the connector and at the light housing eliminating the possibility of contaminants entering the light housing.

Over molding of the connector completely seals the connector and pigtail wiring providing an IP68/IP69K seal against water, dust and corrosion. It also provides a more durable and vibration protected connection.

Automotive Offroad Lighting

Automotive Offroad Lighting