- PRODUCTS

LED Driving Lights

Halo, spot, flood, and mixed beam patterns tested in harsh environments.

LED Headlights

DOT compliant lighting in a variety of sizes, styles, and integrated amber or white halo rings.

LED Light Bars

Curved or straight, 5" to 54" lengths in white and amber for varying conditions.

Accessory Lights

Heavy-duty, waterproof underbody, strip, compartment lights in multiple colors.

LED Work Lights

Featuring a broad range of lumen outputs for light, heavy and extreme duty applications.

Commercial Lights

Interior and exterior lighting with multiple beam patterns, brackets, in AC and DC voltages.

Beacons & Specialty Lights

Safety accessories and specialized lighting solutions for a range of applications.

Vehicle Specific

Lighting kits and mounting options for most truck makes and models.

- INDUSTRIES

- SUPPORT

- ABOUT

- Cart

- Account

Lighting optics

Vision X high output lighting targets the light where you need it and not where you don’t.

How do we get the light where it matters most?

Catalogs are full of LED specifications including lumens, lux and watts to indicate the output of LED lighting. In many LED light designs, a large portion of the LED output is wasted as “stray light”. A key factor in minimizing that wasted light output is effective optics. Vision X uses a system of precision engineered reflectors, optical patterns, and lenses to get all available LED output efficiently on the intended target.

Lens Materials

Vision X uses super high impact polycarbonate lens covers that are up to 5 mm thick and can handle over 200 degrees before deforming. The 92% optically pure lenses are coated with an anti-scratch coating and are also UV stabilized to ensure that they will not yellow over time.

Acrylic Optics

Vision X uses only 94% optically pure acrylic lenses to create optical beam available in 10°, 25°, 40°, 60°, 90° and 30/65° (elliptical) beam patterns. Vision X Lighting’s optics are designed to put light on the intended target.

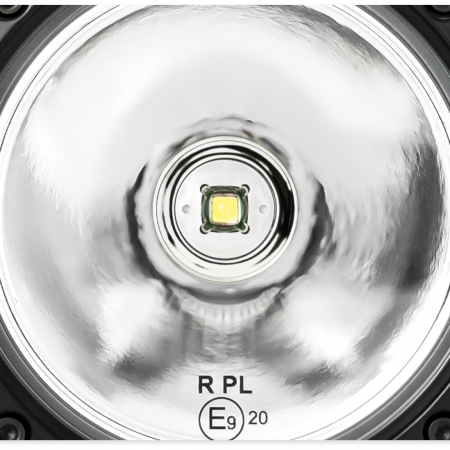

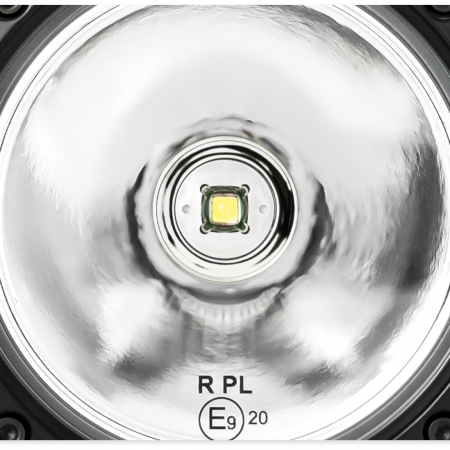

Reflector Technology

Vision X Iris reflector technology is engineered to maximize the output performance from a single LED. The Iris design uses a precise reflector that harnesses the full output of the LED to prove unparalleled distances and effectiveness. This provides usable light distances exceeding 3500 feet.

Photo Biological Testing

Vision X Lighting is IEC 62471 Photo Biologically tested to ensure no effect on human eyes or skin due to UV radiation. Photobiological testing relates to the optical radiation effects of LED on human eye and skin. The test ensures that UV rays are within acceptable levels ensuring a safe work environment.

Beam patterns

10° and 25° Spot

The spot bean pattern is used primarily as a driving light. The narrow bean creates a focal point accompanied by a “halo effect” which adds peripheral lighting. For applications of high-speed travel where seeing long distance is necessary to avoid potential hazards, the 10 degree and 25 narrow beams provide intense distance.

40° Medium Range Flood

The wide beam pattern is the intermediate beam well suited as a multipurpose light. This beam pattern is normally recommended as a driving beam at lower speeds when you need more peripheral lighting. The wide beam also serves as the optimum balance between distance and width for small to medium industrial vehicles.

60° Wide Area Lighting

The extra wide beam pattern is typically used more for large industrial vehicle lighting. It is necessary when looking to light up a very wide path in front of the vehicle. This beam provides a broad beam of light with a short throw distance.

90° Ultra Wide Area Lighting

The ultra wide beam pattern is typically used to maximize a general work area from an elevated position. Typically used in building lighting or when lighting very large work areas. This beam provides a lighting over a very wide area with less distance.

30/65° Elliptical Low Beam Driving

The ultra wide beam pattern is typically used to maximize a general work area from an elevated position. Typically used in building lighting or when lighting very large work areas. This beam provides a lighting over a very wide area with less distance.

Automotive Offroad Lighting

Automotive Offroad Lighting